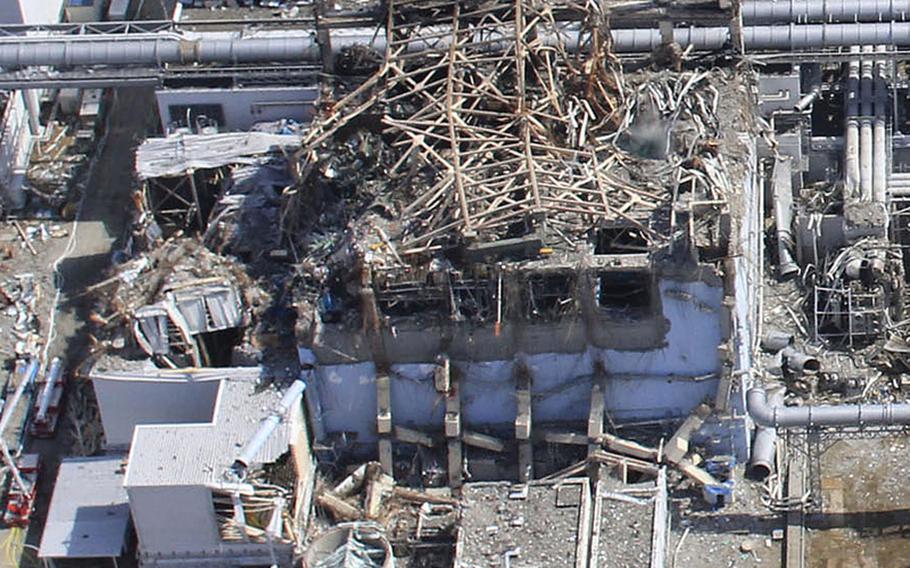

This handout aerial photo dated March 20, 2011, taken by small unmanned drone shows damaged Unit 4, left, and Unit 3 of the crippled Fukushima Daiichi nuclear power plant in Okumamachi, Fukushima prefecture, northern Japan. (Air Photo Service/Abaca Press/MCT )

TOKYO — The science behind the proposed ground freeze at Fukushima’s Dai-ichi nuclear power plant is sound, but a former Air Force engineer planning a much larger project in Canada says it will require precise execution to work.

Creating a frozen wall of soil underground might sound futuristic, but it’s old technology — first used in the 19th century to contain coal mines.

Most ground-freezing projects are much smaller in scale than the nearly mile-long, 90-foot deep wall that Japan is considering to prevent an estimated 400 tons of groundwater from flowing into the power plant’s radiation-contaminated buildings.

However, one project to contain contamination at a Canada oil sands site would dwarf the Fukushima project in scale.

Joseph Sopko, director of ground freezing for engineering firm Moretrench, recently oversaw a pilot project at the Alberta site that required workers to freeze ground down to about 500 feet. If completed, the final project will form an ice wall about 5 miles long.

Sopko, an Afghanistan veteran and retired lieutenant colonel in the Missouri Air National Guard, believes the Fukushima project should work.

“The whole concept is actually really simple,” he said during a phone interview with Stars and Stripes.

On Tuesday, Japan announced it would spend 47 billion yen ($472 million) on Fukushima radioactivity containment, of which 32 billion yen would be spent on the frozen wall, a trade ministry official confirmed with Stars and Stripes.

Although Japanese government officials didn’t release any new technical data Tuesday, a panel hearing in May and examples from projects elsewhere provide an idea of what the project could look like.

The frozen wall would surround the plant, diverting groundwater rolling down nearby hills. A large compressor would cool a refrigerant — ammonia is common — which would then run through a heat exchanger, Sopko said. That would cool a “brine,” for which he often uses calcium chloride.

The cooled brine would run through evenly placed steel pipes, which would then form ice around them.

If the pipes are parallel at about 3 feet apart, the ice joins quickly, forming a barrier. However, the margin of error on keeping the pipes parallel must be small, or the wall will take longer to form.

A 1 percent margin of error is what they shoot for, said Sopko, who added that they were able to meet that standard for the Alberta pilot project.

Compared to similar projects his teams have completed, Sopko said an ice wall on the scale of Fukushima’s proposal should take about a year at the most, depending on the number of drills involved. However, he conceded that it’s more difficult to build a timeframe at Fukushima, because the radiation levels will limit work shifts.

With a corrosion inhibitor and proper material, a properly installed system can last for decades, Sopko said.

The Japanese government could give the Kajima Corp., which proposed the project, the go-ahead to build it after further discussions.

It will be crucial for the company to bring in engineers with experience in identifying soil conditions and the surprises that sometimes pop up during field projects, Sopko said.

“In spite of all the computer modeling and theory … it still takes a lot of technical know-how,” he said.

Slavin.erik@stripes.com Twitter:@eslavin_stripes